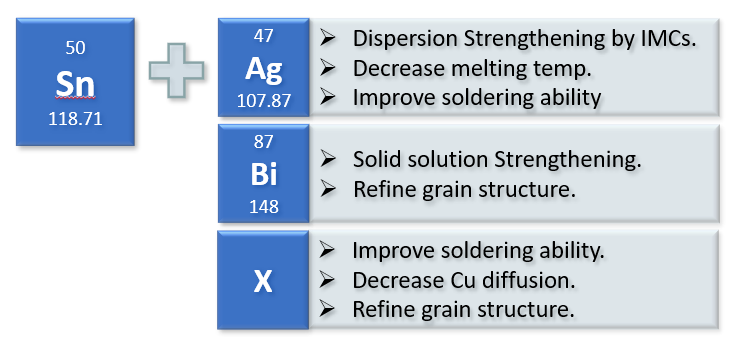

Dr. Ken Lin, Director of SHENMAO’s Advanced Material Development Center, commented, “As electric vehicles continue to evolve, there is an increasing need for more durable solder materials that meet stringent reliability and process window requirements. Concurrently, environmental, social, and governance (ESG) considerations are pushing manufacturers to reduce carbon emissions. To address these challenges, we at SHENMAO are developing innovative soldering solutions that will keep us at the forefront of the industry for the next 50 years.”

In response to the rapidly evolving landscape of packaging technologies, SHENMAO is committed to innovating solder materials that meet current market demands. The company also actively collaborates with well-known EMS factories. Building on decades of experience in related processes and materials, SHENMAO established an independent testing laboratory, CHEETAH Inspection Inc., in 2020. CHEETAH has received ISO/IEC 17025 certification for its laboratory quality management system and specializes in testing and verifying the reliability and failure analysis of various products and processes.

San Lien Lee, Founder, Chairman & Kelvin Li, CEO

SHENMAO specializes in the production of a wide array of solder products to meet diverse industry needs. Our offerings include:

- Water-Soluble and No-Clean Solder Paste

- Laser Solder Paste

- Solder Preforms

- Cored Solder Wire

- Wave Solder Bar Alloys

- Wave Soldering Fluxes

- Extremely Pure Solder Powder up to Type 8

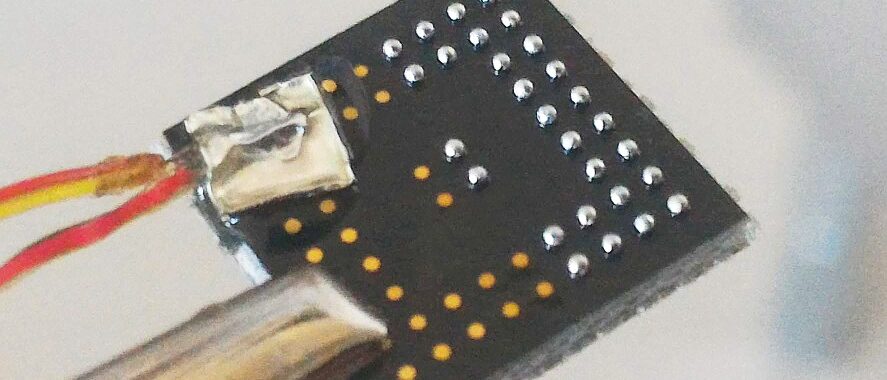

- BGA and Micro BGA Solder Spheres

- Wafer Level Packaging Solder Paste and Fluxes

- LED Die Attach Paste

- High-Performance Liquid Fluxes

- Solar Ribbon

- Plating Anodes

These products are designed for use in various processes, including PCB fabrication, assembly, and semiconductor packaging.

For more information, please visit www.shenmao.com.