Does the electric current have any effect on the solder during solidification?

Our solders were used for further research. This time it was about the Influence of Electric Current at Solidification of Solder.

The Department of Microelectronics at the Technical University in Brno is still conducting research and we are glad that our soldering materials can contribute to their testing.

This work deals with the investigation of influence of electric current flow on the inner structure of solder alloy SAC305 during solidification. Methodology of this experiment was as follows:

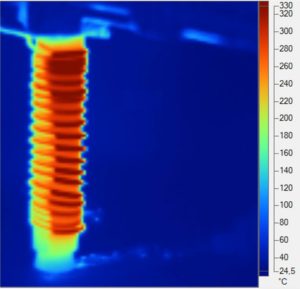

- Establishment of experimental melting station (Figure 1) constructed of quartz tube, resistance wire (heating element – Kanthal), electrodes (braze) and stage.

- Verification of homogenous temperature distribution on quartz tube (Figure 2).

- Melting of SAC305 solder alloy up to temperature 300 °C.

- Solidification of solder WITH and WITHOUT electric current. The value of the electric current was 7.5 A. the final sample had the shape of a cylindrical ingot.

- After the samples preparation, the metallographic cross-sections were done. Chemical wet etching was used for highlighting of the inner structure.

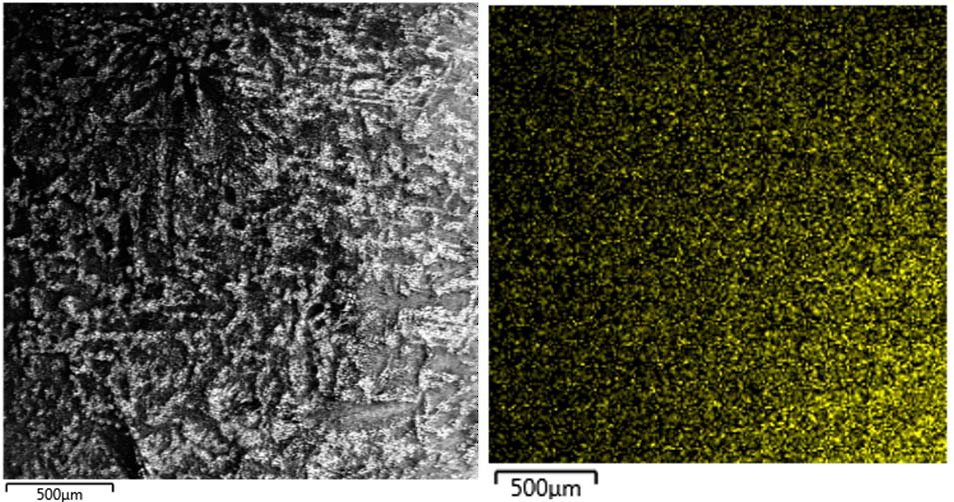

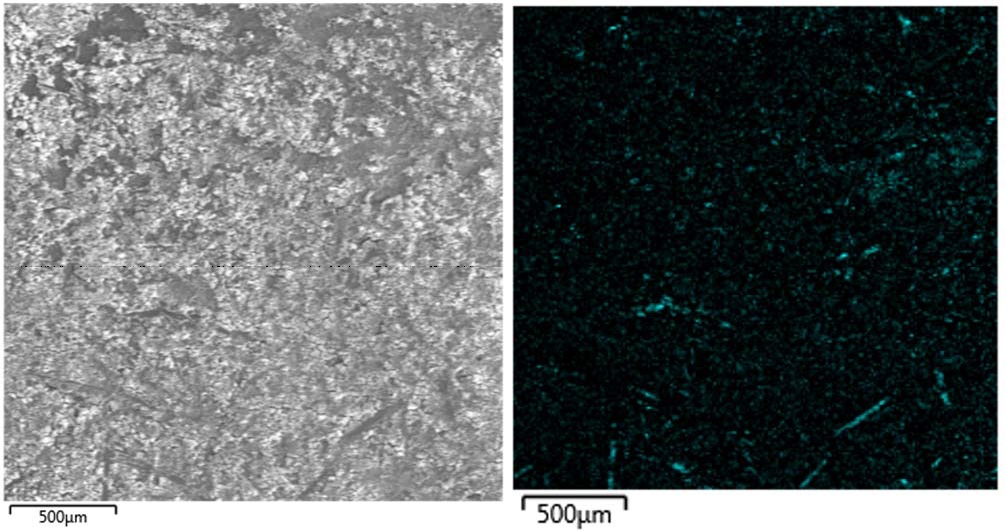

Prepared samples were analyzed by SEM (Scanning Electron Microscope) and EDX (Energy Dispersive X-Ray). Results showed that the sample without connected electric current during solidification had regular arrangement of β Sn dendrites (Figure 3 – SEM). On the contrary, the sample with connected electric current during solidification showed greater disorder in β Sn dendrites grow (Figure 4 – SEM). Moreover, intermetallic parts from the braze electrodes were dispersed in the bulk solder of ingot in comparison to the sample without connected electric current (Figure 4 – EDX) where the intermetallic parts were observed only at the bottom side. These results are preliminary for the further research of this phenomenon.

The full paper is available at the link: https://ieeexplore.ieee.org/document/8810308

We thank the team from the University of Brno and look forward to further interesting tests of our soldering materials.